Understanding the Importance of Electrical Insulation Tape for Safety

Electrical insulation tape is an essential tool designed to offer protection and insulation for various types of electrical wires and cables. Commonly known as insulating tape, it plays a crucial role in ensuring safety within both professional environments and everyday household applications. By preventing electrical shorts and protecting against moisture and abrasion, this tape is a vital component in maintaining the integrity of electrical systems.

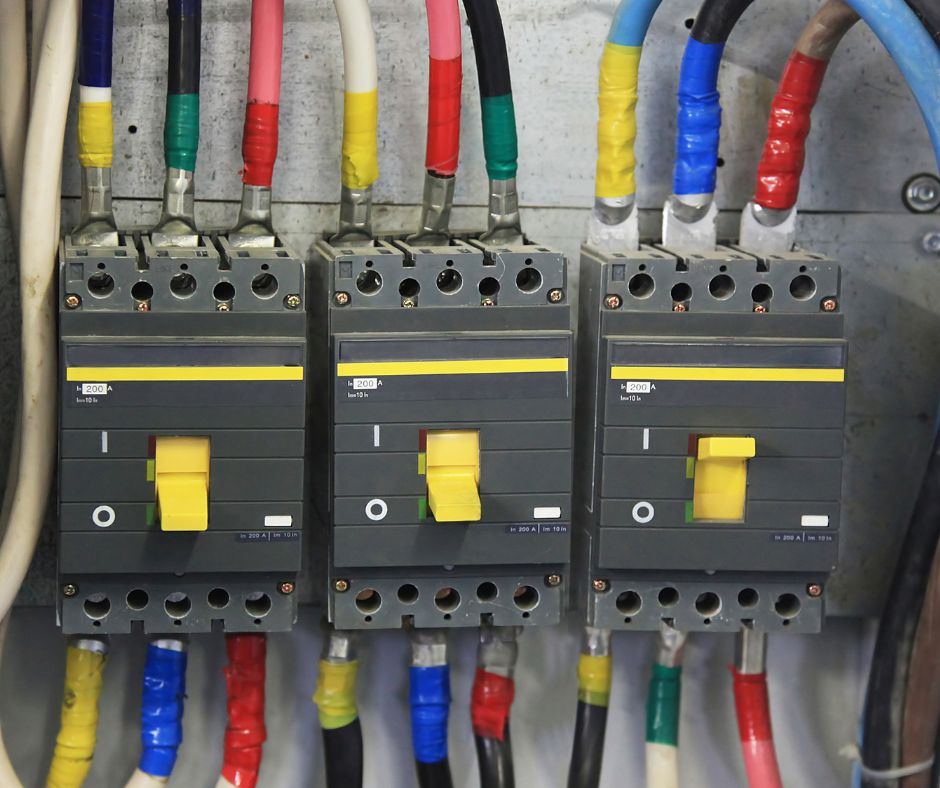

This tape is available in a wide array of sizes and lengths, crafted from different materials, and comes in a variety of colors. These options not only allow for effective insulation but also enable easy identification and organization of cables, thanks to color-coding. Utilizing different colors can help you quickly locate specific wires, making your electrical work more efficient and organized.

Can Electrical Tape Melt? Understanding the Conditions

The short answer is yes; electrical tape can indeed melt under specific conditions. In this article, we will provide a comprehensive overview of the temperature limits of electrical tape, explain the circumstances under which it can melt, and highlight key signs of overheating to keep an eye on.

Exploring the Temperature Thresholds of Electrical Tape

Like many materials, electrical tape has its limitations in terms of temperature. Most standard electrical tapes can withstand temperatures up to approximately 80°C, although some heavy-duty variants may endure slightly higher temperatures. If the temperature exceeds this threshold, the tape's structural integrity may begin to deteriorate.

When electrical tape reaches its maximum temperature limit, it starts to lose its effectiveness. This degradation can manifest in various ways, such as melting, developing a gooey texture, or, in severe cases, leading to complete failure. It's crucial to be aware of these limits to ensure safe and effective use.

For extreme conditions, high-temperature varieties of electrical tape are available. For instance, heat-resistant tape made from materials like fiberglass or silicone can withstand temperatures of up to 200°C or more, providing essential protection in high-heat applications.

Also Read: Keep Your Pets Safe Around Electricity

Get a Quote Today!

Inquire About Our FREE Electrical Inspections

Identifying the Causes of Electrical Tape Melting

Electrical tape can melt due to various factors, primarily resulting from exposure to excessive heat. Understanding these causes is essential for ensuring safe usage. Here are some of the most common reasons for tape melting:

Understanding Excessive Heat Exposure and Its Effects

The most apparent reason for melting electrical tape is exposure to high heat. If electrical tape is placed near hot surfaces, engines, or any heat-generating components, it may start to soften, bubble, or even melt completely. Additionally, electrical systems, such as power circuits, can produce more heat than the tape is designed to withstand, especially during malfunctions or overload situations.

Therefore, if you’re using electrical tape in proximity to high-temperature areas, it is advisable to double-check the temperature ratings of the tape to prevent potential failures.

The Impact of Degradation Over Time on Electrical Tape

Electrical tape is not built to last indefinitely. Over time, the adhesive and the material can degrade, especially when exposed to UV light, moisture, or other harsh environmental conditions. This degradation can diminish the tape's insulating capabilities. As the tape ages, it might lose its effectiveness and become susceptible to melting even at lower temperatures than it would normally handle.

Regular wear and tear are part of the lifecycle of electrical tape. Hence, it is crucial to routinely inspect for signs of aging or damage.

How Improper Application Can Lead to Tape Failure

Using electrical tape under less-than-ideal conditions can lead to its premature failure. For instance, if the tape is wrapped too tightly, applied in areas exposed to friction or heat, or over-stretched during application, its effectiveness may be compromised. Additionally, wrapping the tape around sharp edges or applying it on components that can overheat, such as light bulbs or electrical outlets, can lead to problems unless specifically rated for those uses.

Also Read: 10 Ways to Save On Power And Energy Costs

Recognizing the Signs of Overheating Electrical Tape

If you suspect your electrical tape is overheating, there are several key signs to look out for. Here are the most common indicators that your tape may be melting or experiencing excessive heat:

The Sticky or Tacky Texture of Overheated Tape

One of the first signs of melting electrical tape is a noticeable change in texture, specifically a sticky or tacky feel. This change is often a precursor to further degradation.

Discoloration as a Sign of Heat Damage

Overheating electrical tape may also exhibit discoloration. You might observe a transition from its standard black or colored appearance to brown, dark gray, or even black. This change occurs as the heat causes the tape's PVC or other materials to break down. Catching this issue early can save your wires from further damage; if ignored, it can lead to melting or fire hazards.

Bubbling or Distortion Indicating Excessive Heat

If electrical tape begins to bubble, distort, or warp, it is a clear sign that heat is adversely affecting it. This typically occurs when the heat causes the adhesive or plastic layers to separate or break down. The surface may appear wavy or uneven, signaling that temperatures are exceeding safe levels. If you notice these bubbles, it’s prudent to contact your electrician for further evaluation.

Detecting a Burning Smell from Electrical Tape

A burning smell around electrical tape is a significant warning sign. This odor may resemble plastic melting or rubber burning. When excessive heat causes the adhesive to break down, the resulting fumes can be alarming. Do not ignore this warning. If you smell burning, it could indicate that the tape is on the verge of melting or even catching fire.

Visible Smoke as a Serious Warning

If you observe smoke emanating from the electrical tape, it is a clear indication that the heat levels are far beyond what the tape can handle. Smoke signifies that the tape has likely started to melt or may even be on fire. At this critical point, it is essential to turn off the power source immediately and reach out to your electrician for assistance.

Remember – Never use water to extinguish an electrical fire. Instead, utilize a CO2 fire extinguisher for safety.

Immediate Steps to Take if Electrical Tape Melts

In the event that your electrical tape does melt, the first critical step is to disconnect any power sources or turn off any equipment to ensure safety.

Prioritizing safety is paramount, as electrical hazards can pose severe risks.

After ensuring safety, always consult your electrician for guidance. If the tape was installed by a professional, they may need to inspect the area for underlying electrical issues that could have contributed to the problem.

Exploring Alternatives to Electrical Tape for High-Heat Applications

If you are working in environments where temperatures frequently exceed the limits of standard electrical tape, it is wise to consult your electrician about suitable alternatives. Here are a few options to consider:

- Heat-resistant silicone tape: This variety is designed to withstand higher temperatures and is ideal for applications where heat is a concern.

- Fiberglass tape: A highly durable option that can endure extreme temperatures without compromising performance.

- Mica or ceramic insulation: For the highest level of heat protection, specialized insulations like mica or ceramic may be the best choice.

Key Takeaways on Electrical Tape Melting Risks

Ultimately, electrical tape can indeed melt, primarily due to excessive heat exposure. Understanding the temperature limits of your tape and ensuring you select the appropriate type for your specific application is crucial for preventing issues.

By being mindful of signs such as discoloration, stickiness, or unusual smells, you can take swift action to mitigate risks. Always prioritize safety and contact your local electrician for expert advice when needed.

Get a Quote Today!

Inquire About Our FREE Electrical Inspections

It’s interesting to see how often we overlook the basic tools that ensure our safety in various environments, like electrical insulation tape. I remember a DIY project where I was trying to redo some old wiring at home. I used multiple colors of tape not just for insulation but also to keep track of which wires were meant for what function. It made a huge difference when troubleshooting.

That’s a great point about using different colors of tape for tracking wires during a DIY project. I’ve learned from experience that a little organization can save so much time and confusion later on. I once tackled a similar wiring project, and I made the rookie mistake of not labeling. I had to backtrack way too many times, which could have been avoided with a simple system in place.

It’s so true how easy it is to overlook the simple tools that play a critical role in our safety. When I took on a similar DIY project last summer, I found myself getting really frustrated with a tangle of wires. I didn’t think to use colored tape until it became a mess, so I ended up scrambling to figure out what went where. Your approach of using different colors not only sounds efficient but smart in preventing headaches later on, too.

I really appreciate the insights shared about electrical insulation tape. It’s fascinating how something as simple as tape can play such a critical role in safety and functionality, particularly in our increasingly tech-driven environments. I’ve often found myself using different types of electrical tape during DIY projects at home and it’s made me realize how essential it is in preventing accidents.

It’s interesting how something like electrical insulation tape can end up being a key player in our projects, isn’t it? You’re spot on about how this seemingly simple material is actually crucial for safety and functionality. When you think about it, it’s like the unsung hero of the DIY world.

It’s interesting to think about how often we take tools like electrical insulation tape for granted. I remember a project I worked on where I had to repair some old wiring in a vintage lamp. Using the right tape not only ensured safety but also gave me some peace of mind knowing those connections were secure. It’s amazing how something so simple can significantly affect the long-term functionality and safety of electrical setups.

You hit the nail on the head about how we overlook the unsung heroes of the DIY world, like electrical insulation tape. It’s like the quiet friend at a party who ends up saving you from embarrassing moments. And that vintage lamp project sounds like a blend of nostalgia and good ol’ tinkering.

It’s great to hear about your experience working with that vintage lamp. You touched on something important: how easy it is to overlook the role of basic tools like electrical insulation tape in our projects. When repairing old wiring, you don’t just have to focus on the visible damage; it’s also about ensuring that even the smallest components, like the tape, are up to the task.

You’re right on the mark about the often-overlooked details in our projects. It’s interesting how something as simple as electrical insulation tape can play such a crucial role. When I started working on that vintage lamp, my focus was primarily on the aesthetics—restoring the lampshade and polishing the base. It wasn’t until I delved into the wiring that I realized just how critical each small component is.

You bring up such an interesting point about the basic tools in our projects. I’ve found over time that it’s often those small, seemingly insignificant components that can make the biggest difference in the long run. When I was working on that lamp, I was surprised at how much the integrity of the wiring depended on the quality of the tape. A lot of people focus solely on the aesthetics or the major components, but neglecting something like electrical tape can lead to issues down the road.

This is such a relevant topic, especially in today’s world where we rely heavily on electrical systems at home and work. I remember when I first started wiring my own home office; I underestimated the importance of electrical insulation tape until I faced a minor short circuit! It really brought home how vital this simple tool is for both safety and organization.

You make a great point about how vital electrical insulation tape is. I had a similar experience when I started working on DIY projects around my house. It’s interesting how something so simple can have such a big impact on safety and functionality. That minor short circuit could have led to much bigger issues if not for the precautions we take.

Your exploration of electrical insulation tape highlights not only its practical uses but also its significance in ensuring safety in our electrical systems. It’s interesting to consider how something so seemingly simple can play such a pivotal role in both professional settings and daily life.

The thorough exploration of electrical insulation tape’s role in ensuring safety and organization in both professional and residential installations is indeed timely, especially given the increasing complexity of modern electrical systems. It’s fascinating to consider how a seemingly simple tool can significantly impact not just the efficiency of electrical work, but also the broader context of electrical safety.

It’s fascinating to delve into the often-overlooked but crucial role that electrical insulation tape plays in our daily lives, both in professional settings and at home. I’ve found that understanding these basic tools is essential for anyone working with electrical systems, whether out of necessity or simply as a hobby.

I appreciate the focus on electrical insulation tape and its critical role in both safety and organization. It’s interesting how something so simple, like tape, can have such a significant impact on our electrical systems. I remember when I was rewiring some old lamps in my home; I had a mix of vintage wires and modern components. The color-coding was a lifesaver for keeping things straight, especially when I had to keep track of what connected where—it made troubleshooting so much easier!

It’s fascinating how something as seemingly simple as electrical insulation tape can have such a significant impact on safety and efficiency in our daily lives. I recently tackled a small home renovation project, and I found myself relying on color-coded electrical tape to keep track of wires. It made a challenging task much more manageable!

You bring up an interesting point about the role of color-coded electrical tape in home projects. It’s striking how a tool that seems so straightforward can transform a daunting renovation task into something more manageable. Using different colors for wires is a practical approach, allowing you to distinguish between them at a glance. This not only helps in organizing but also adds a layer of safety, reducing the risk of connecting the wrong wires.

This is a really interesting topic! I’ve always found it fascinating how something as simple as electrical insulation tape can have such a significant impact on safety and organization. A while back, I was rewiring a few old lamps at home, and I realized how handy color-coded tape was for tracing wires—definitely made the process less of a headache.